Pressure treated deck boards are still the workhorse of backyard decks across Utah, giving you the classic wood look without blowing the budget. When you understand how this material is made, how to choose the right boards, and how to install them correctly, you can build a deck that looks great and holds up to Utah’s sun, snow, and everything in between.

The Ultimate Guide to Pressure Treated Deck Boards

When building a beautiful, long-lasting deck, choosing the right material is the most important decision you’ll make. For decades, homeowners and contractors have relied on pressure treated deck boards for their unbeatable combination of affordability, strength, and durability.

Honestly, that combination is exactly why they remain the most popular decking material in America. Here’s what you need to know:

- Affordable: Cost significantly less than composite, cedar, or exotic hardwoods

- Durable: Resist rot, fungal decay, and termite damage for years

- Strong: Can support more weight and span longer distances than cedar or redwood

- Versatile: Can be painted, stained, or left to weather naturally

- Available: Easy to find in standard sizes at most lumber yards

Key Specs at a Glance:

| Feature | Details |

|---|---|

| Common Sizes | 5/4 x 6″, 2×6″, various lengths 8′-20′ |

| Treatment Types | Above-grade (.25), Ground-contact (.40), Below-grade (.60) |

| Lifespan | 15-40+ years depending on maintenance |

| Cost | Lowest among common decking options |

| Best For | Deck framing, posts, joists, decking surface |

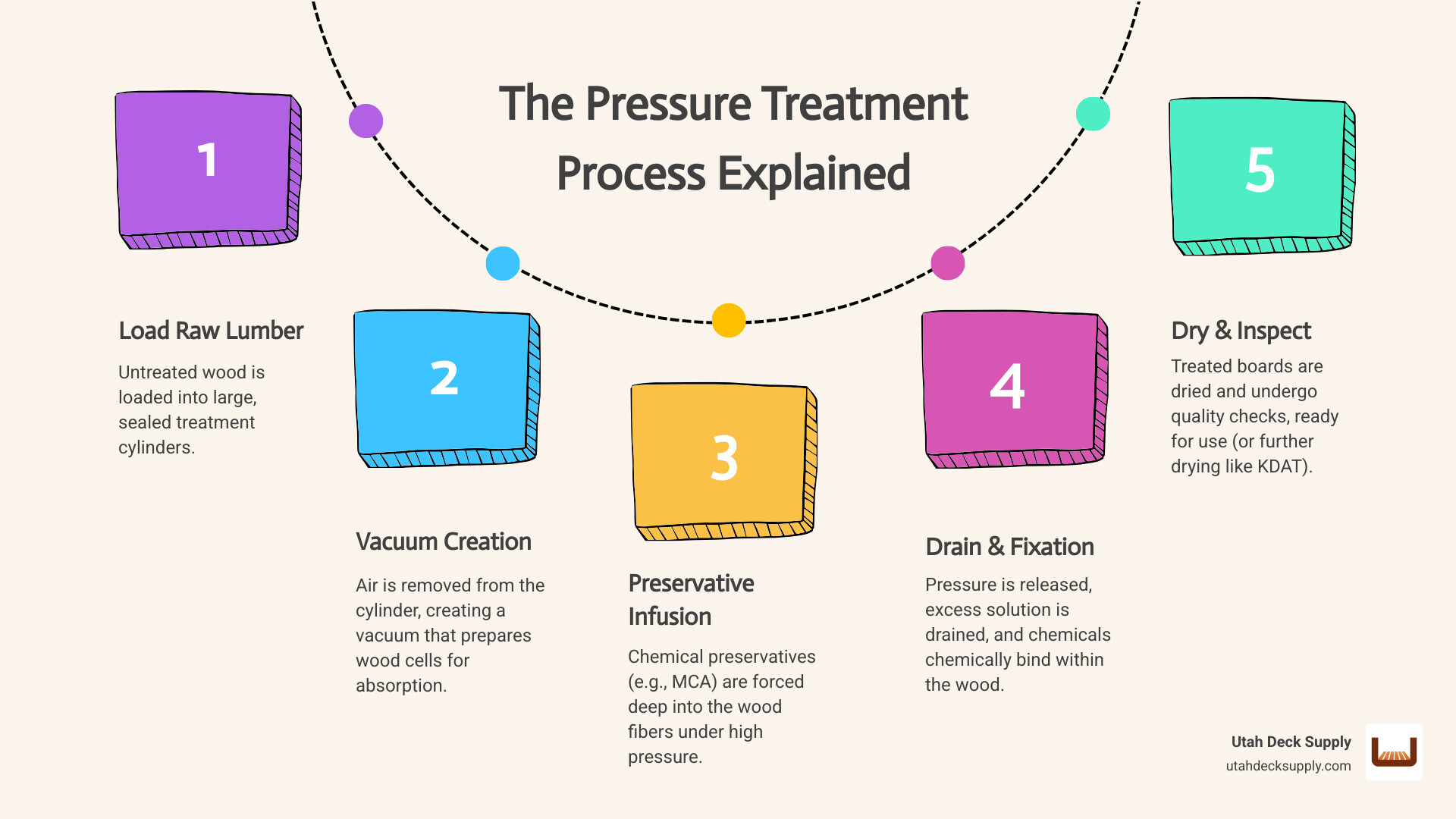

You know what? More than 70% of decks in America use pressure-treated lumber. The treatment process works by removing air from the wood under pressure, then forcing chemical preservatives deep into the wood fibers. Modern preservatives like Micronized Copper Azole (MCA) protect against moisture, insects, and decay while being certified safe for residential use.

The main challenge? Pressure-treated lumber often arrives from the mill very wet. This moisture can cause boards to warp, cup, and twist as they dry—unless you know how to select, store, and install them correctly.

What is Pressure-Treated Wood and Why Use It?

At its core, pressure-treated lumber is wood that has undergone a specialized process to infuse it with chemical preservatives. American eBuilder details the treatment process, noting that boards are put into a tank to remove air before flushing with chemicals and water to resist moisture and insects.

Here’s the thing: untreated wood, especially common softwoods like pine, is naturally susceptible to decay, rot, and insect infestation. When exposed to moisture and the elements, it deteriorates quickly. Pressure treatment allows the wood to last significantly longer.

The primary reasons we use pressure-treated lumber for decking are:

- Protection Against Rot and Fungal Decay: Preservatives penetrate deep into wood fibers, creating a barrier that fungi and bacteria cannot easily break down

- Termite and Insect Resistance: Chemicals in pressure-treated wood are toxic to pests, deterring them from damaging your deck

- Improved Durability: By preventing biological breakdown, pressure treatment dramatically extends the service life of the wood

- Cost-Effectiveness: Frankly, pressure treated deck boards cost the least among common decking materials

- Structural Strength: PT lumber can support substantial loads and span longer distances compared to many other types of wood

For a broader comparison of options you can see in our West Jordan showroom, check out Decking Materials Compared: Pros and Cons.

Choosing and Handling Your Pressure Treated Deck Boards

Selecting the right pressure treated deck boards is paramount to building a deck that stands the test of time. It isn’t just about grabbing the first bundle off the rack; a little discernment goes a long way.

Here’s how to choose better quality boards:

- Inspect for Straightness: Look down the length of each board to check for bows, twists, and cups

- Examine the End Grain: Look for boards with tight, uniform growth rings. Avoid boards with the “pith” (dark center)

- Check Moisture Content: Choose boards that feel lighter and appear drier. KDAT boards are excellent if you want to avoid excess moisture

- Avoid Defects: Steer clear of boards with large knots, splits, or excessive wane

- Consider the Grade: For decking, you’ll typically want #1 or premium grade

For more detailed selection advice, Family Handyman offers 10 Tips for Choosing and Buying Deck Lumber.

Once you’ve selected your boards, proper storage before installation is critical:

- Store Flat and Off the Ground: Lay boards on a level surface, ideally on concrete

- Use “Stickers” for Airflow: Place small wood pieces perpendicular to boards, creating gaps between layers

- Protect from Elements: Cover with a tarp but leave sides partially open for ventilation

- Weight Down the Stack: Put concrete blocks on top to keep boards flat as they dry

- Allow Time to Acclimate: Give boards at least a week or two to acclimate before installation

Installation and Maintenance for a Long-Lasting Deck

Installing pressure treated deck boards correctly is just as important as selecting them. Proper installation helps your deck handle Utah snow loads, dry heat, and day-to-day use.

Key installation practices:

- Ensure Proper Drainage: Design framing so water sheds away from the house with a minimum slope of 1/4 inch per 12 feet

- Orient Boards Correctly: Install boards with growth rings curving up (“frown down”) to shed water better

- Proper Spacing: Butt wet boards tightly together; leave 3/16 inch gap for dried or KDAT boards

- Use Appropriate Fasteners: Always use fasteners rated for pressure-treated lumber. Utah Deck Supply stocks Deck Screws that match common PT formulations

- Straighten Warped Boards: Use board-straightening tools to pull boards straight across joists during installation

Ongoing maintenance extends your deck’s life:

- Cleaning: Clean annually with deck cleaner or oxygen-bleach solution

- Sealing or Staining: After boards dry sufficiently, apply quality stain or sealer with UV protection

- Inspecting for Damage: Periodically check for loose fasteners or signs of decay

For more detailed care steps, see Deck Maintenance Tips: Keeping Your Investment in Top Shape.

Advanced Topics: Treatment Types, KDAT, and Safety

Understanding Treatment Levels: Ground Contact vs. Above-Grade

When choosing pressure treated deck boards, you’ll see different treatment levels, mainly “Ground Contact” and “Above-Grade.” Understanding this is crucial for your deck’s longevity.

| Treatment Type | Retention Level | Typical Uses |

|---|---|---|

| Above-Grade | .15 – .25 pcf | Decking surface, railings, balusters |

| Ground-Contact | .40 pcf | Deck posts, joists, beams, stair stringers |

| Below-Grade | .60 pcf | Support posts buried directly in ground |

For your deck’s substructure—posts, beams, and joists—use ground-contact rated lumber. These components need maximum protection. While decking surface can often be above-grade lumber, many Utah builders opt for ground-contact throughout for added peace of mind.

The team at Utah Deck Supply can walk you through AWPA standards, show you compatible Joist Hangers, and help pick the right treatment level for each part of your project.

Is KDAT Right for Your Pressure Treated Deck Boards?

KDAT stands for Kiln-Dried After Treatment. This lumber is dried in a kiln after the pressure treatment process.

Key benefits of KDAT:

- Improved Stability: Less prone to warping and twisting

- Ready to Finish Sooner: Can stain or seal much sooner than standard PT lumber

- Lighter Weight: Easier to cut and handle on the jobsite

- Reduced Shrinkage: Experiences less shrinkage after installation

The downside is cost—KDAT is more expensive than standard PT lumber. Honestly, it comes down to priorities. If you want to minimize warping and get stain on quickly, KDAT can be a smart investment. For lower-budget projects, standard PT might be the better fit.

Utah Deck Supply can help you compare Lumber options and decide whether KDAT is right for your project.

Safety and Environmental Considerations

Modern pressure-treated lumber is much safer than older formulations, but responsible handling is still important. Today’s primary preservative, Micronized Copper Azole (MCA), is certified for residential use.

Follow these safety precautions:

- Wear PPE: Use gloves, dust mask, and safety glasses when cutting or sanding

- Wash Hands: After handling, wash thoroughly before eating or drinking

- Work in Ventilated Area: Cut and sand outside or in well-ventilated spaces

- Clean Up Debris: Collect sawdust and scraps instead of leaving them scattered

Never burn pressure-treated lumber. Burning can release toxic chemicals. Dispose of scraps according to local waste-management guidelines.

For extra peace of mind, review Utah Deck Supply’s Deck Safety Checklist: Ensuring Your Deck is Secure.

Your Deck Project, Perfected

Pressure-treated lumber remains a top choice for a reason, offering strong value and a classic wood aesthetic that fits everything from starter homes in West Valley City to custom builds in Draper. Honestly, the key to success is knowing how to select the best pressure treated deck boards, store them correctly, and install them with the right fasteners and spacing.

With the right knowledge and high-quality materials, you can build a durable, beautiful deck that avoids common pitfalls like warping and premature wear. The experts at Utah Deck Supply can help you select the perfect pressure-treated lumber and all the necessary Deck Hardware for your Utah home, whether youre in Salt Lake City, Provo, St. George, or anywhere in between.

If youd like to see options in person and compare boards, fasteners, and railing systems side by side, stop by our showroom. For personalized advice, span guidance, and a complete materials list custom to your project, call us at 385-993-5492 or Request a Free Quote today.